Campaigns to raise awareness of packaging sustainability and recyclability are one of the main themes that Lumson has integrated into its mission. One of the avenues being pursued is the creation of refill systems, which are playing an increasingly important role in the company's launch plans.

Consumers already regularly use refill systems - just think of the food industry, which introduced refillable products years ago. What's more, refills create interaction with consumers and make it possible to personalize products.

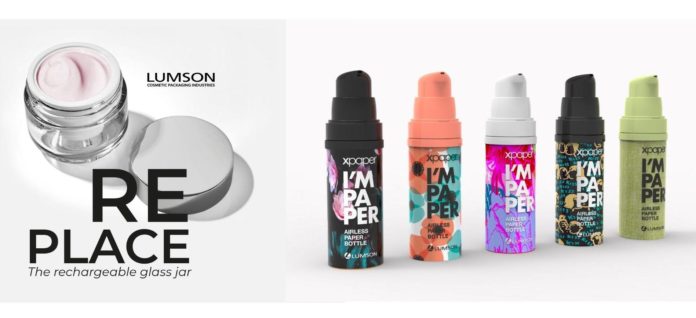

Recharging, Lumson's new frontier

Re Place, Lumson's new glass jar with a refillable system (inner cup), is designed for easy removal and replacement, and offers a response to market expectations. "In new circular design systems, refills are an effective solution given their extremely positive impact on the environment, while encouraging new, more ethical and virtuous habits among more attentive consumers. "explains Lumson CEO Matteo Moretti.

Re Place is the first research system in a series to come, because "for Lumson, redesigning, rethinking new refill systems will increasingly become a priority, and demonstrates our unwavering commitment to sustainability, without neglecting the product's technical, aesthetic and protective functions."

Lumson, which has long focused on the 3Rs of the circular economy - reduce, reuse, recycle - has adopted three new key concepts for the refill sector: Re-Think, Re-Gen, Re-Act.

Re-Think: rethinking packaging with an eco-design approach. Re-Gen, to breathe new life into glass jars. Re-Act, to enable consumers, who are playing an increasingly active role, to personalize their product by simply replacing the inner cup.

Re Place uses two 50 ml Lumson glass jars: Deluxe and Unique, whose respective features are an elegant, classic shape and rounded lines with a refined look. Both feature an extremely thick jar base for a positive approach to luxury.

The inner plastic cup - which has been specially designed to allow protection to be applied to the top - can, after use, be easily removed from the jar and disposed of via the recycling channel.

Both components can be customized - giving the various packaging elements a distinctive, eye-catching identity - using a variety of effects and decorations: from simple but elegant silk-screen printing, to more sophisticated interior lacquering that enhances and adds value to the lines and thickness of the glass.

Cardboard for airless

The Italian company also innovates in the airless sector, with carton packaging. Its XPaper pocket airless received the ADI Design Index Award for Innovation.

The innovative nature of XPaper is essentially due to the material from which the airless dispenser bottle is made: cardboard. According to Lumson, it wasn't easy to find an alternative to plastic or glass that was lightweight, easy to work with, durable and compatible with the strict safety protocols established by the cosmetics world.

If paper was not the best material to use for packaging (primary) cosmetics, due to the problems of preserving the formulas they contain, innovative, high-performance and highly aesthetic solutions have emerged. What's more, thanks to fine printing techniques, it's possible to transform any material into a luxurious, sophisticated product that enhances both content and container. All this, while respecting the environment.

The new Xpaper paper airless dispenser is currently the subject of a patent application. It is part of the Touchless family of airless dispensers featuring Lumson's patented hermetic closure.

"I feel XPaper has everything it takes to become an iconic product: it's durable, functional, safe and sought-after, says Matteo Moretti. Once the product is used up, you can separate the dispenser from the paper bottle and send it to the right recycling chain. It's practical and safe to use, because like all our airless dispensers with pouch, it's been developed to protect the product as much as possible against the risk of contamination by air or other external agents that could alter the formula. And then there's the look. The packaging can be customized using conventional and digital printing technologies, transforming itself into a unique product with a strong personality."