Plasmatreat presents a new application of its Openair-Plasma technology, successfully implemented in the luxury packaging sector to optimize the finishing and printing process for luxury perfume glass bottles, as well as the bonding of their decorative elements.

The Openair-Plasma technology developed by Plasmatreat is one of the world's leading solutions for activating, cleaning and plasma-treating all types of surface in a wide range of applications. A simple, environmentally-friendly method, Openair-Plasma is an activation process that enables effective, rapid and affordable surface modification, without altering the mechanical properties of the materials treated.

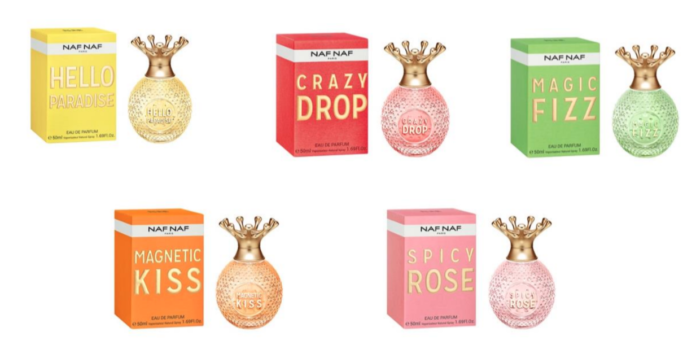

Developed to meet the needs of bottle manufacturers, this new business application aims to improve the print quality of text characters and logos for luxury brands with often highly refined designs, and provide maximum protection for vials and bottles to prevent damage and scratches caused by friction during transport. The process can even be used to produce complex multi-part bottles.

The Plasmatreat process is based on in-line activation of the plasma treatment. It directly treats, cleans and activates the entire surface of glass vials, resulting in a high-quality design that is both efficient and cost-effective for the manufacturer.

"In fact, one of the advantages of Openair-Plasma technology is that it is a cost-effective process. pThis allows the robotized printing and gluing of small decorative elements to take place directly after cleaning and processing, without any interruption to production.the company says.

The glass used is generally produced from primary colors (white, green or brown) to make the bottles and flasks more sophisticated, an essential aspect in the cosmetics industry. This glass is then tinted. For this type of packaging, high quality is required to enable the color to be properly applied. The Openair-Plasma process contributes to the efficiency of the lacquering process generally carried out in the luxury sector with high-quality paint.

In the final stage of the manufacturing process, the glass is coated to prevent damage and scratches. These glass bottles are then mainly screen-printed. The type of coating applied during manufacture determines the quality of adhesion of the printing ink used.

To ensure good adhesion and uniform color dispersion, particularly on polymer coatings, plasma activation is required to increase surface tension. "Thanks to its robust nozzle system and simple in-line integration, Openair-Plasma technology is the perfect solution for the surface activation required for glass in perfume bottles and flasks".Plasmatreat emphasizes.

From a technical point of view, these applications require Openair RD1004 plasma nozzles, each with a wide nozzle head and a working width of 40 mm. The components move along under the nozzles at the constant speed of the conveyor system.

With the Openair-Plasma process, manufacturers of luxury perfume bottles can benefit from a system that offers several advantages:

- Surface micro-cleaning to remove impurities and adhering organic particles.

- Use of innovative coating processes and alternative color systems (UV varnishes, solvent-free lacquers).

- Better ink adhesion when screen-printing or pad-printing on glass, even on polymer-coated bottles.

- Improved design.

- Production of complex multi-part bottles.

- Reduced rejection rate (error rate).

- Easy integration of plasma nozzles into coating systems.

Ultimately, in cosmetic applications, and more particularly in the luxury sector, this surface treatment and cleaning method can prove highly advantageous for obtaining very high quality glass and exclusive, high-end designs.