Skinobs' half-yearly audience report outlines preclinical and clinical claims in cosmetics for the first half of 2024.

For years, beauty testing services have been influenced by many drivers, from technological advances such as optical innovations, AI, biomarker discovery to consumer expectations. Pre-clinical testing and clinical studies enable ingredient and cosmetics brands to communicate product performance to their customers, giving the evaluation of product tolerance or efficacy a highly strategic position in the launch development process.

Skinobs' half-yearly audience report provides an overview of claim trends in the cosmetic testing sector, based on user searches on the Skinobs platform, for preclinical testing (in silico, in vitro, or ex vivo...) and clinical (in vivo).

The report is based on searches carried out by over 7,700 users in 89 countries, using data from the 400 laboratories and 1,000 methods referenced on the platform.

Users of the Skinobs platform, whether R&D managers, formulators, evaluation or marketing managers, come mainly from Europe (over 72 %), the Americas (21 %), Africa (5 %) and Asia (2 %). However, there has been an increase in searches in Asia, explained by the fact that Skinobs referenced various Asian laboratories in the first half of 2024.

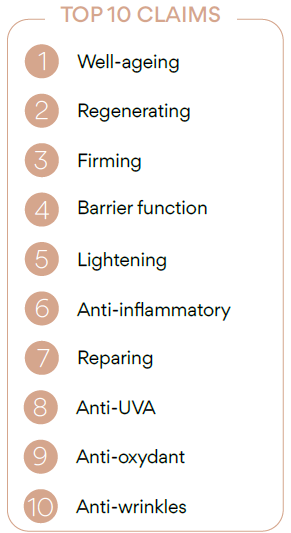

1. Pre-clinical trials - new ageing claims emerge

Changing market trends in the beauty industry have led to significant advances in preclinical evaluation methods. These methods, which include in silico, in tubo, in vitro and ex vivoThese tests evaluate factors such as safety, stability, biodegradability and efficacy. Key developments stem from a better understanding of skin biology and the discovery of biomarkers, as well as innovative testing platforms. These platforms facilitate cell-based testing, cocultures and sophisticated models such as 3D skin constructs and organ-on-a-chip systems using microfluidics. By incorporating neurons, capillaries and other skin elements, these models offer increased complexity and more accurate, real-world testing conditions.

At the start of 2024, some of the most sought-after new claims appeared, such as "regenerating", "firming", "brightening" and "repairing", taking precedence over the dominant "anti-aging" claim.

This shift reflects a move towards a more holistic approach, known as "well-ageing". Rather than focusing on fighting the signs of aging, this trend emphasizes maintaining skin health, natural beauty and well-being. This shift in discourse appeals to consumers who are increasingly looking for products that promote long-term care and well-being, rather than short-term solutions, and a more balanced and realistic view of aging.

In terms of the type of tests carried out, we are seeing a diversification in the types of tests performed. More specifically, consultancy services, UV in vitro and physical and chemical analyses are on the increase. This trend is accompanied by a significant reduction in traditional efficacy testing, which has fallen by 17 percentage points. This decline allows for a more balanced distribution of tests in other areas, notably safety assessments, microbiological analysis, UV testing, and so on. in vitro and specialized efficacy evaluations, such as those focused on hair care.

The increase in consulting services, which rose by six percentage points, underlines the growing importance brands place on expert advice. Regulatory service providers assess compliance with safety and environmental standards, efficacy and claims that ingredients or finished products must validate through testing protocols. They are therefore first-rate partners in helping cosmetics and ingredients brands bring their products to market. They are therefore partners of choice to support brands in the development of their cosmetic products. In addition to confirming claims, they are also at the origin of new ideas that enlighten and serve marketing semantics, making it possible to build a factual, differentiating discourse adapted to the profound changes in lifestyles and consumption patterns.

UV testing in vitro have also taken on growing importance as a public health issue. This category of tests is uniquely governed by ISO Good Standard Practice, which guarantees the consistency and reliability of assessment methods worldwide (with exceptions in certain regions). Whatever the mechanism of action studied, the industry is progressively adopting a hybrid assessment approach combining tests in vitro studies in vivo. This approach is facilitated by innovations in increasingly sophisticated and specific skin models. These 3D skin models can now include elements such as capillaries, neurons and specificities linked to sensitivity, age or pigmentation, enabling a more accurate representation of skin reactions. These technological developments not only improve the accuracy of assessments, but also their variety, as these improved models provide more comprehensive and reliable data.

Overall, there is less research into efficacy testing, and a more even split with other test categories. The increased importance of research in consulting services reflects a shift towards informed, science-based product development. At the same time, the increase in research into UV in vitro shows the importance of these evaluations as a guarantee of correct and safe use by consumers. These research trends collectively illustrate a dynamic and evolving approach within the cosmetics industry, driven by the need for ever-greater safety, scientifically-proven efficacy and alignment with holistic and informed consumer demands.

2. Clinical evaluation: the rise of the "ageing well" claim

In the field of clinical evaluation, developments are equally important. The issue of inclusivity is influencing the way products are tested worldwide on multiple skin types in multi-center studies. Consumers are increasingly concerned that ethical considerations should be taken into account and that tests on humans should not be too extensive.

We see a similar increase in the importance of research into the "ageing well" claim, which has risen by 18 percentage points. This confirms a growing shift towards a more holistic approach to skincare, focusing on overall wellbeing rather than simply combating the visible signs of aging. The demand for beauty routines that act holistically is helping to develop new tests based on neuroscientific approaches. There is a very strong trend towards measuring emotions using neurosensory analysis based on 3 complementary components: expressive, subjective and physiological.

As a result, searches for traditional claims such as hydration drop by 32 percentage points, giving way to more specific wellness claims such as firming, anti-pollution and antioxidant benefits. These new areas of interest emphasize not only the aesthetic aspects of skincare, but also the importance of protecting the skin against environmental factors and promoting long-term health.

Biometrological testing remains at the forefront of research, accounting for 48 % of all tests, although this figure is down from 55 % in 2023. Despite this decline, the split is now more balanced between consultation (9 %) and tolerance testing (8 %).

Underlining the growing importance of oral hygiene in personal care habits, there was also a 4-point increase in oral care effectiveness tests. This increase reflects the growing interest in dental care and oral health. Brands are focusing more on the efficacy and safety of oral care products, responding to consumer demand for complete health solutions that go beyond skin care to include dental wellness as a crucial part of personal care.

This report highlights the changing landscape of cosmetics testing and provides valuable advice to brands and industry players, helping them to align their product development strategies with emerging consumer demands and preferences.

Overall, these changes signify a paradigm shift in the science of beauty, emphasizing a holistic understanding of human biology and its link to beauty. They testify to the industry's commitment to innovation and integration, thanks to technological advances and a better understanding of human physiology.

The cosmetics industry has always prioritized consumer, biometrological and scientific evaluations to meet the innovation imperative. Testing technologies are the foundation of product innovation, improving marketing and communication standards. They push back the boundaries of product claims and raise expectations of product efficacy. The factors that define cosmetic products are the active ingredients, the formulation and the overall proposition, which depend on substantiated claims.

Skinobs, a platform launched in 2016

Skinobs is the leading referencing platform for preclinical and clinical tests. The aim of the platform is to offer beauty professionals worldwide an intuitive, free database of all testing solutions for skin, nails and hair. A comprehensive, independent tool, Skinobs offers two platforms dedicated to preclinical testing (in silico, in tubo, in vitro or ex vivo) and clinical evaluation (in vivo to optimize product development in terms of performance, cost, speed and innovation.

Main photo: AdoreBeautyNZ / Pixabay