The French group Novair, a global manufacturer of on-site oxygen and nitrogen generators, and American Oxygen, a start-up developing ceramic technologies for gas separation by ionization, have signed a strategic partnership agreement to industrialize and market an ionic oxygen generator by the end of 2024. As part of this partnership, Novair will invest in the capital of American Oxygen, and the partners will set up a joint venture dedicated to the manufacture of ionic oxygen generators.

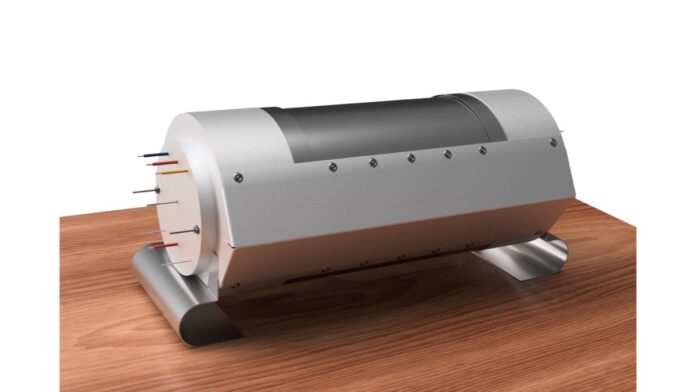

The ionic oxygen generator is reliable, ultra-compact and easy to use (plug and play). According to its designers, it is based on the greatest technological innovation in the field of air gases since the invention of cryogenic distillation over 100 years ago.

Technology developed in collaboration with NASA

The technology was originally developed by American Oxygen in cooperation with NASA for use during astronauts' spacewalks on the moon or in space.

The ionic oxygen generator produces ultra-pure oxygen (from 99.99% to 99.9999%) from ambient air, using a ceramic membrane with the property of selectively conducting oxygen atoms through its wall. The oxygen produced is generated spontaneously under pressure, without a compressor, "an unprecedented technological feat.

The ionic oxygen generator is designed for the most demanding industrial, laboratory and healthcare applications. A breakthrough innovation in the air gases market, this generator aims to provide an autonomous, affordable, low-carbon, ultra-reliable oxygen supply. It eliminates dependence on liquid or bottled gas deliveries.

"At a time when access to high-purity oxygen has proved crucial for many activities in healthcare, research and industry, we are delighted to be partnering with American Oxygen. It will enable us to reach a new milestone, giving as many people as possible access to a revolutionary innovation that enables the on-site production of ultra-pure oxygen using a reliable, easy-to-use device".says Bernard Zenou, President of Novair.

"This technology is the product of many years of R&D and collaboration with Nasa, and was initially developed to produce oxygen on the International Space Station. It was the Covid-19 pandemic that accelerated the design of a first demonstrator to produce medical oxygen, this time on Earth. Today, the technology is mature and ready for industrialization. Together with Novair, the world's leading player in the oxygen generator market, we are very proud to bring to market this new oxygen production technology, which will provide access to high-purity oxygen for all industries and hospitals, everywhere in the world". continues Dale Taylor, President of American Oxygen.

A buoyant global market

The global oxygen market1 - estimated at nearly $70 billion - is growing steadily, and is expected to record an annual growth rate of over 9 % to reach over $125 billion by 2028. Essential for treating severe cases of illness, demand for medical oxygen increased considerably during the Covid-19 pandemic. Oxygen is also used in a wide range of industries for its combustion, oxidation and fermentation properties. Growing demand for pure oxygen in laboratories, fiber optics and semiconductor manufacturing is contributing to market growth.

1. https://www.valuemarketresearch.com/fr/report/industrial-oxygen-market

Photo taken from the American Oxygen website (www.amox.us).